Even the best furnace and filler alloy can’t overcome poor joint design. In brazing, joint geometry and fit-up directly determine how the filler metal flows, wets, and bonds. Optimizing this design up front is one of the most effective ways to improve quality, consistency, and joint strength.

Capillary Action: The Foundation of Brazing

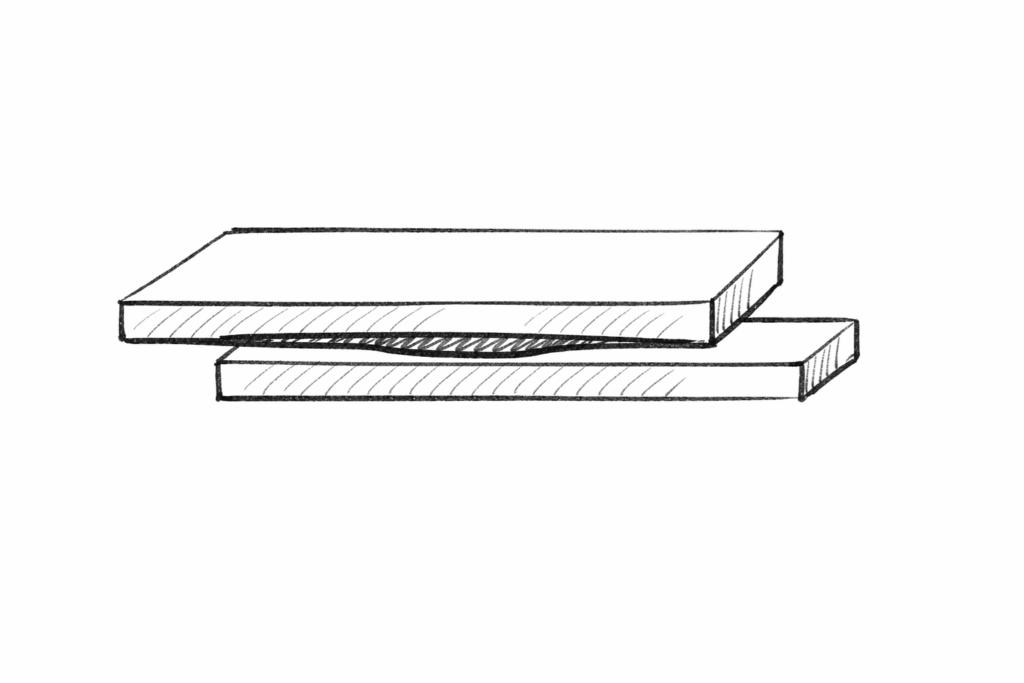

Unlike welding, brazing depends on capillary action to draw molten filler metal into the joint gap. That means joint clearance—the small space between the two components—is critical.

If the clearance is too tight, the filler metal can’t flow properly. If it’s too wide, the filler may not bridge effectively, leading to voids or weak joints. The ideal gap typically ranges between 0.000″ and 0.005″, depending on the materials and braze alloy being used.

Design Considerations for Reliable Joints

Reliable brazed assemblies start with smart engineering. Key design considerations include:

Consistent Fit-Up

Parts should maintain uniform gaps to ensure even filler flow and strong, continuous bonding.

Surface Cleanliness

Contaminants such as oil, oxides, or scale can block filler flow and prevent proper wetting.

Joint Accessibility

Fillets, corners, and recessed areas should allow filler entry and venting of trapped gases.

Thermal Compatibility

Select base materials and braze alloys with similar expansion rates to prevent cracking or stress during heating and cooling.

The Role of Process Control

Even the best joint design will fail without a controlled process. That’s why controlled atmosphere brazing—performed in high-purity hydrogen and nitrogen environments—is essential for oxidation-free results. Uniform heating ensures capillary flow across all joints, even in complex or multi-part assemblies.

At Franklin Brazing & Metal Treating, our engineering team works directly with customers to refine joint design from prototype through production. Every assembly is inspected and qualified to AWS C3.6, AWS C3.14, and ASTM standards, ensuring complete filler penetration and verified bond integrity.

Designing for Long-Term Performance

Strong brazed joints aren’t accidental—they’re engineered. By aligning geometry, materials, and process control, manufacturers can achieve durable, clean, and reliable joints that perform under pressure. That’s the standard we uphold at Franklin Brazing: precision-built joints that last.

Get in Touch with Us

Need help improving joint reliability or solving a brazing challenge? Contact Franklin Brazing’s engineering team for expert consultation on design, materials, and process optimization.